Muaj kaum lossis ntau pua tus nqi sib txawv rau cov khoom ua si yas uas zoo li zoo ib yam ntawm lub khw. Vim li cas thiaj muaj qhov sib txawv?

Nws yog vim cov khoom siv yas sib txawv. Cov khoom ua si yas zoo siv ABS yas ntxiv rau cov khoom noj khoom haus-qib silicone, thaum cov khoom ua si yas pheej yig zoo li yuav siv cov yas rov ua dua tshiab.

Yuav ua li cas xaiv cov khoom ua si yas zoo?

1. Cov ntxhiab tsw, cov yas zoo tsis muaj ntxhiab tsw.

2. Saib cov xim, cov yas zoo yog ci thiab cov xim zoo nkauj dua.

3. Saib daim ntawv lo, cov khoom tsim nyog yuav tsum muaj 3C ntawv pov thawj.

4. Saib cov ntsiab lus, cov ces kaum ntawm cov khoom ua si yog tuab thiab tiv taus ntau dua.

Ntxiv nrog rau cov kev txiav txim yooj yim no, cia kuv qhia luv luv rau koj tias muaj cov khoom siv yas no siv hauv cov khoom ua si. Koj tuaj yeem xaiv raws li cov ntawv sau ntawm cov khoom thaum koj yuav lawv.

1. ABS

Peb tsab ntawv sawv cev rau peb yam khoom ntawm "acrylonitrile, butadiene thiab styrene" feem. Cov khoom no muaj qhov zoo ntawm qhov ruaj khov, hnav tsis kam, tsis kam ua haujlwm, tsis muaj tshuaj lom, tsis muaj mob, tsis kub thiab corrosion kuj, tab sis nws yog qhov zoo tshaj plaws tsis txhob scald nrog boiling dej, vim hais tias nws yuav saj los yog deform.

2. PVC

PVC tuaj yeem yog tawv lossis mos. Peb paub tias cov kav dej kav dej thiab cov kav dej infusion yog txhua yam ua los ntawm PVC. Cov qauv duab uas xav tias ob qho tib si mos thiab tawv yog ua los ntawm PVC. Cov khoom ua si PVC tsis tuaj yeem tua cov dej kub npau npau, lawv tuaj yeem ntxuav ncaj qha nrog lub tshuab ntxhua khaub ncaws, lossis tsuas yog so nrog cov ntaub qhwv hauv dej soapy.

3. PIB

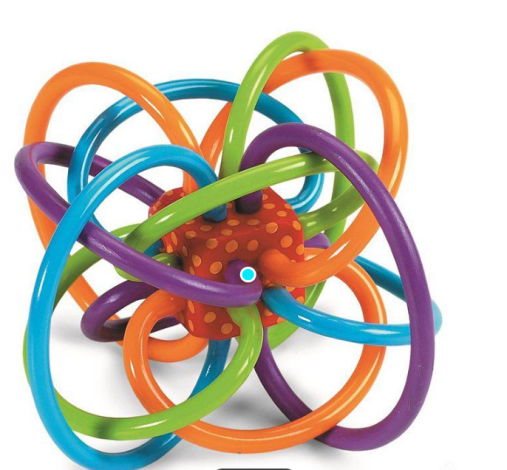

Cov me nyuam lub raj mis yog tsim los ntawm cov khoom siv no, thiab cov khoom siv PP tuaj yeem muab tso rau hauv lub qhov cub microwave, yog li nws yog siv los ua lub thawv, thiab nws kuj yog feem ntau siv rau hauv cov khoom ua si uas cov me nyuam noj tau, xws li teethers, rattles, thiab lwm yam sterilize los ntawm boiling hauv dej kub.

4. PE

Mos PE yog siv los ua cov hnab yas, hnab yas, thiab lwm yam, thiab tawv PE yog tsim rau ib zaug txhaj tshuaj molding khoom. nws yog siv los ua slides lossis rocking nees. Cov khoom ua si zoo li no yuav tsum tau molding ib zaug thiab hollow hauv nruab nrab. Thaum xaiv cov khoom ua si loj, sim xaiv ib zaug molding.

5. EVA

Cov khoom siv EVA feem ntau yog siv los ua cov lev hauv pem teb, cov lev nkag, thiab lwm yam, thiab tseem siv los ua npuas lub log rau cov menyuam yaus.

6. PUV

Cov khoom no tsis tuaj yeem yog autoclaved thiab tsuas yog ntxuav me ntsis nrog dej sov.

Peb daim duab: 90% ntawm cov khoom yog ua los ntawm pvc. Lub ntsej muag: ABS / yam tsis muaj qhov tawv:; PVC (feem ntau yog 40-100 degrees, qhov qis dua, cov khoom siv softer) lossis PP / TPR / daim ntaub ua qhov me me. TPR: 0-40-60 ° C. Hardness tshaj 60 degrees rau TPE.

Tau kawg, muaj ntau cov ntaub ntawv yas tshiab tau siv rau cov khoom ua si. Thaum niam txiv yuav, tsis txhob txhawj yog lawv tsis paub lawv. Txiav txim raws li plaub txoj kev uas peb tau hais los saum toj no, thiab nrhiav cov tub lag luam uas muaj ntawv pov thawj thiab cov npe. Qhib koj ob lub qhov muag thiab yuav cov khoom ua si zoo rau koj tus menyuam.

Cov me nyuam txoj kev loj hlob ntawm lub cev thiab lub hlwb yog ua tiav los ntawm kev ua ub no. Cov khoom ua si tuaj yeem txhawb kev loj hlob ntawm cov menyuam yaus thiab txhim kho kev txaus siab ntawm kev ua ub no. Thaum cov menyuam yaus tsis muaj kev cuam tshuam rau lub neej tiag tiag, lawv kawm txog lub ntiaj teb los ntawm cov khoom ua si. Yog li ntawd, cov niam txiv yuav tsum xaiv cov khoom ua si nyab xeeb thaum xaiv cov khoom ua si.